Semiconductors and Electrical Applications

Many applications require the measurement of electrical parameters whilst making microscopic or spectroscopic observations. At Linkam, we’ve been creating sample characterisation solutions for the microelectronics and semiconductor fields for many years.

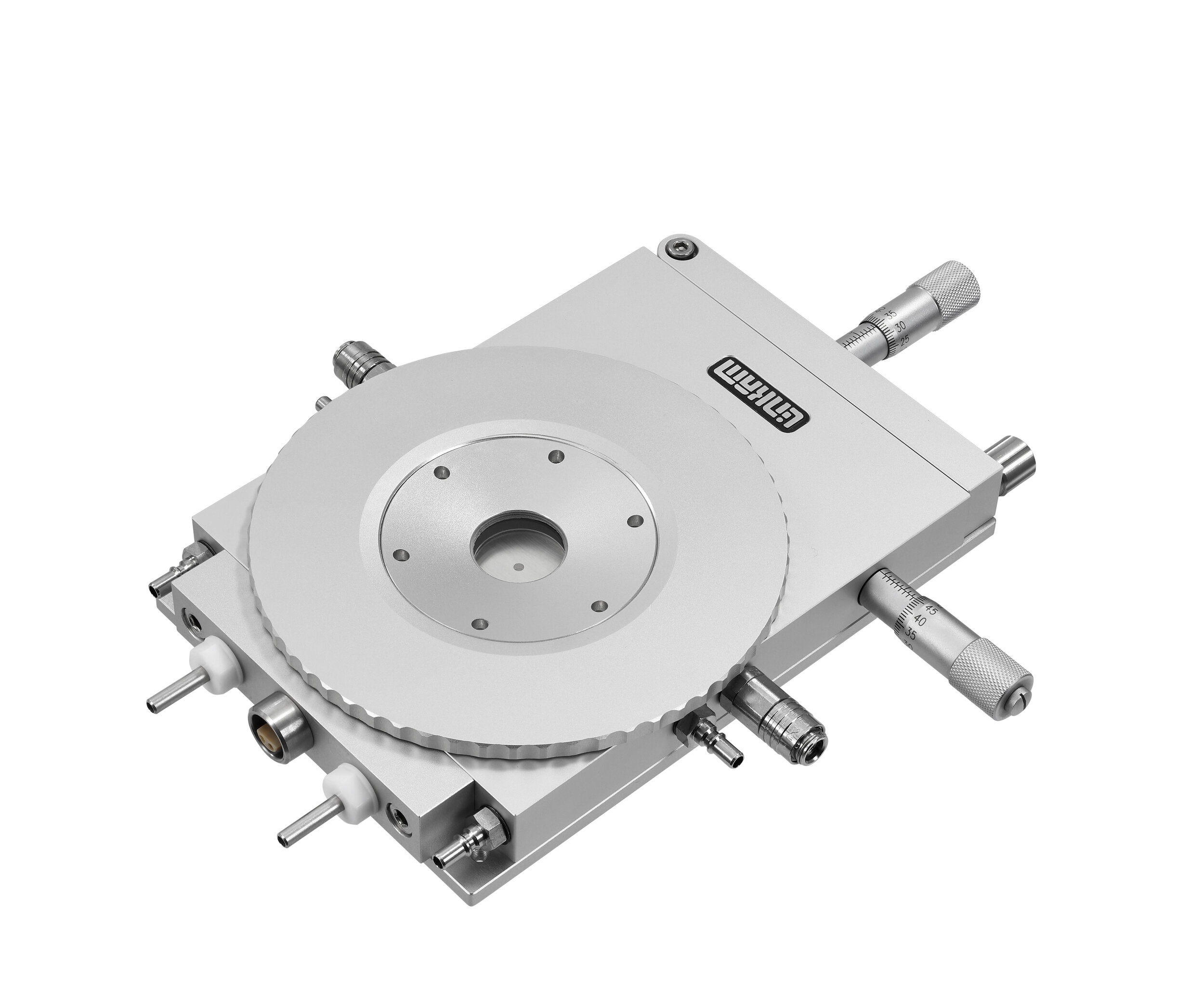

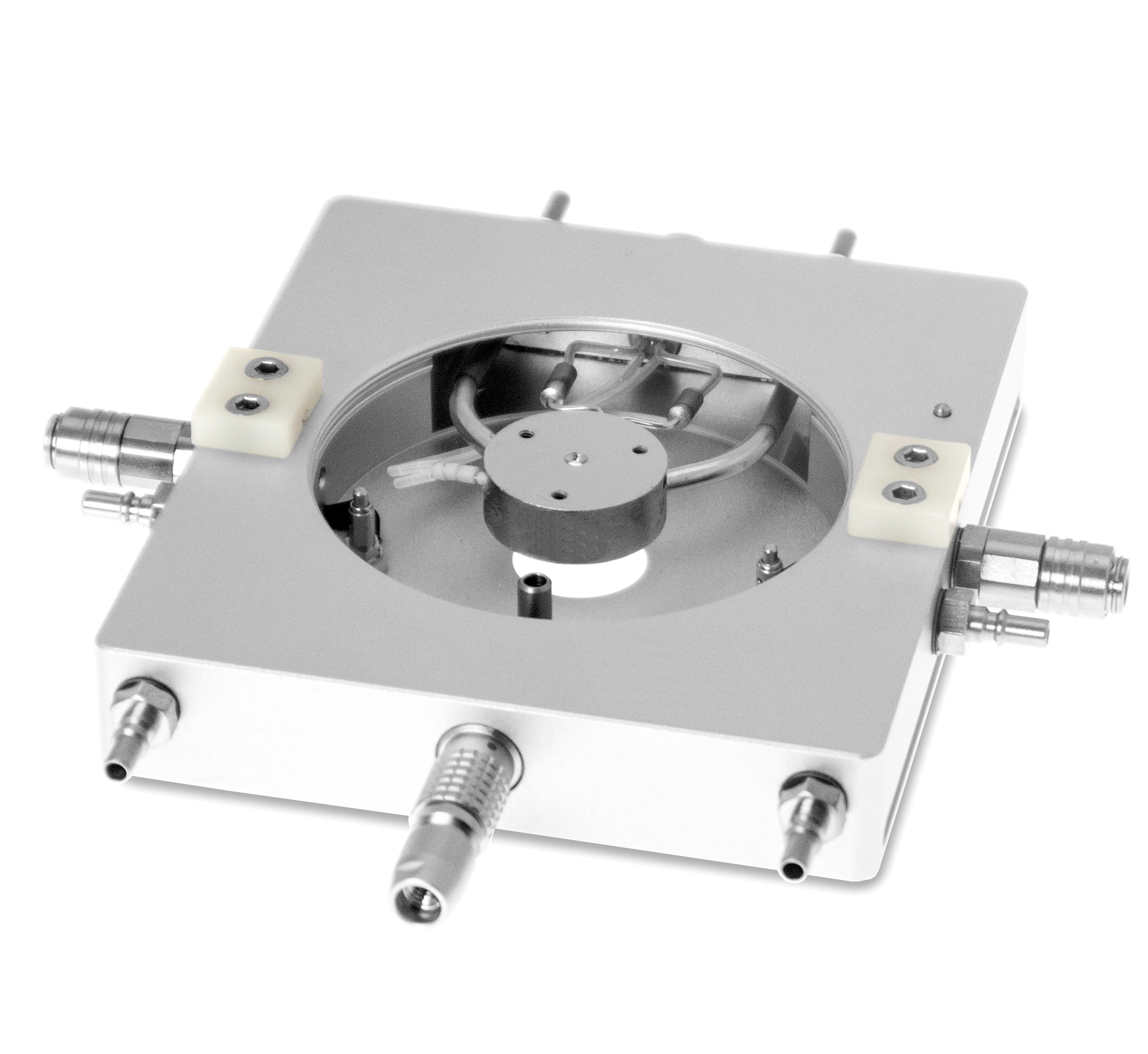

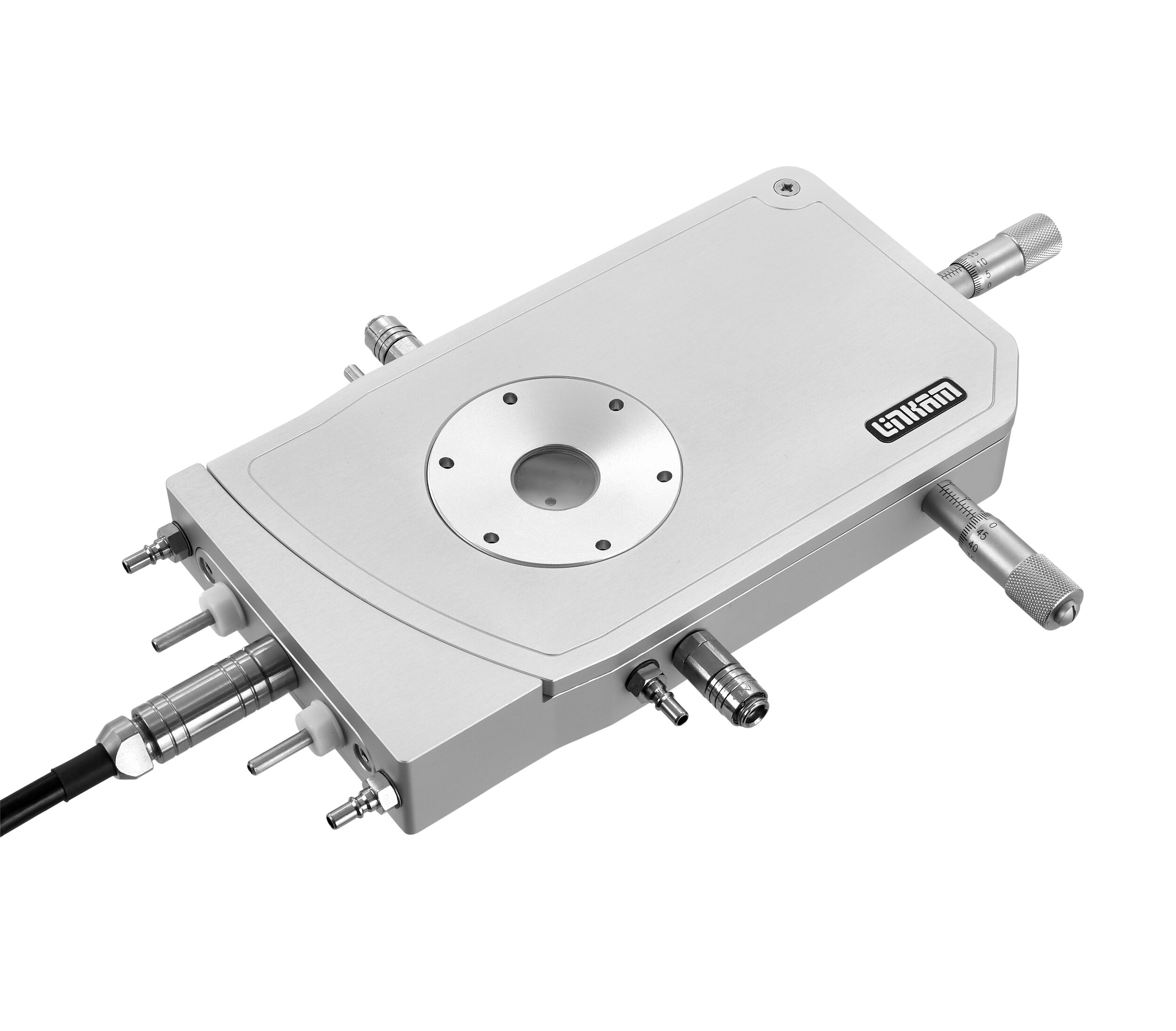

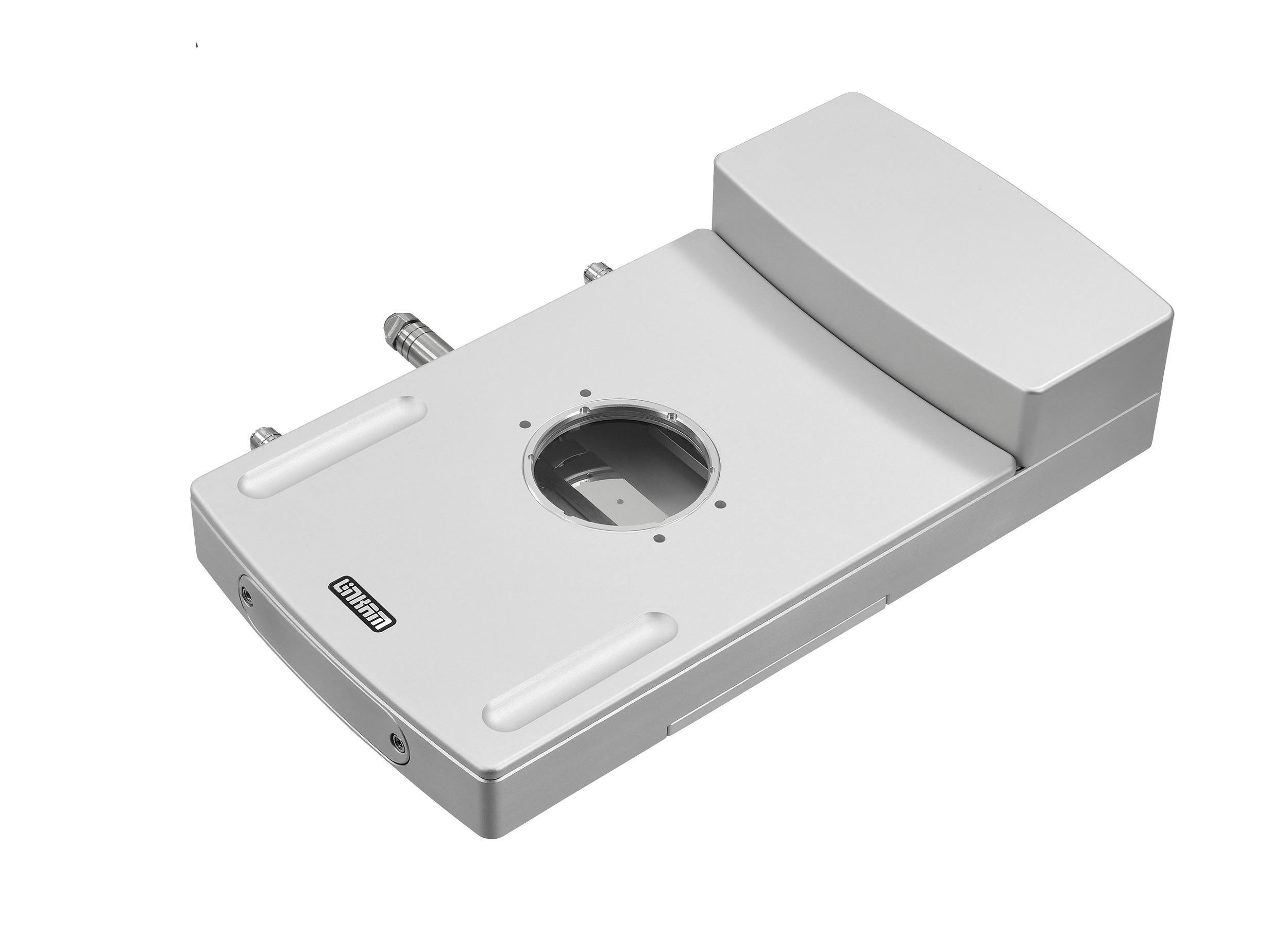

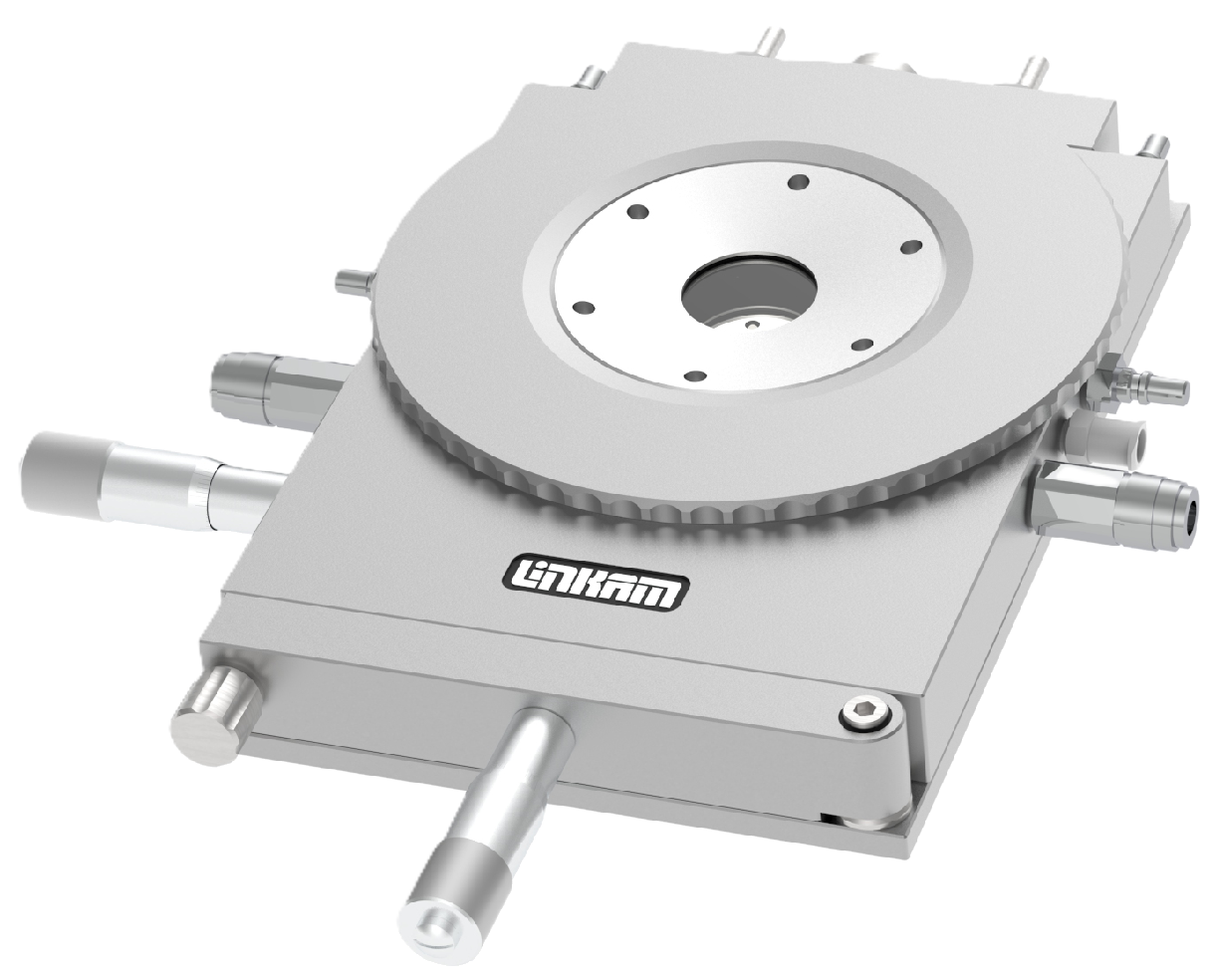

We design and manufacture sample characterisation chambers with accurate temperature control ranging from < -195°C to 1500°C. The environment within the chamber can be controlled, with options for gas purging, controlled vacuum or humidity. Linkam stages can be fitted with electrical connection or gold tipped tungsten needle probes allowing the measurement of the electrical properties of the sample and their change with temperature.

Linkam systems are compatible with light microscopy and spectroscopy techniques including Raman, FT-IR and X-ray.

Related Products

Published Papers

Researchers used a Linkam LTS420E-PB4 stage, which incorporates a temperature control element and positional tungsten probes, to study the effect of temperature on metal halide perovskite (MHP) performance and conduct electrical measurements.

Integrating a Linkam THMS600E stage into their custom in-house setup Wang et al. were able to obtain temperature-dependent Photoluminescence to evaluate the moisture assisted degradation of the phosphor at 200 °C and 100% RH.

Researchers have demonstrated a new highly-controllable method for fabricating high quality air-stable phosphorene films with a designated number of layers ranging from a few down to monolayer using Linkam’s THMS600.

Researchers investigated III-nitride tunable cup-cavities supporting quasi whispering gallery modes from ultraviolet to infrared using Linkam’s THMS600

Researchers investigated double-twist cylinders in liquid crystalline cholesteric blue phases observed by transmission electron microscopy using a Linkam heating/freezing stage.

Researchers investigated controlling Gaussian and mean curvatures at microscale by sublimation and condensation of smectic liquid crystals using a Linkam heating/cooling stage.

Researchers investigated Vertical Interface Induced Dielectric Relaxation in Nanocomposite (BaTiO3)1-x:(Sm2O3)x Thin Films using Linkam’s HFS600E-PB4

Researchers explored how temperature-controlled experiments play an important part in characterising and understanding the behaviour of next-gen photovoltaic devices using Linkam’s HFS600E-PB4.

Researchers used Linkam’s HFS600E-PB4 probe stage at temperatures down to -70 °C (200K), to investigate how temperature-dependent phase transitions affect the properties of piezoelectric materials, finding that ideal properties peaked around the low-temperature phase transitions.

Researchers study the effect of thermal excitation on semiconducting sensor materials using a Linkam probe stage, the HFS600E-PB4. They explore the temperature sensing performance of these semiconductor nanofilms.

Application NOTES

Learn how Radiant Technologies and Linkam collaborated to improve HFS600E-PB4 stage.

With increased pressure on the electronics sector to deliver greener technology with uncompromised performance, materials research and development has stepped up to the fore.

In this tech note, Linkam and Sensofar demonstrate their collaboration in producing an experimental setup for temperature-controlled optical profilometry experiments.

Linkam’s THMS600H and RH95 were used to observe the effect of temperature and humidity on perovskite photovoltaic films by researchers at the University of Swansea.

Researchers in Australia found that metastable silicon states achieved by indentation remained stable up to 450 °C using a THMS600.

Researchers at the US National Renewable Energy Laboratory (NREL) use Linkam LTS series stages to study the temperature dependent properties of solar cells.

Researchers use the RH95 and THMS600-H to investigate phase change materials for semiconductor applications.

Researchers in Lausanne, Switzerland, used Linkam’s mechanical testing system to study the effect of temperature on the adhesion of transparent thin film electrodes on polymers.

Need More Information?

Complete the form below and one of our technical sales experts will be in touch shortly.